How Smart Labels are Revolutionising Inventory Management

Tuesday 6th August '24

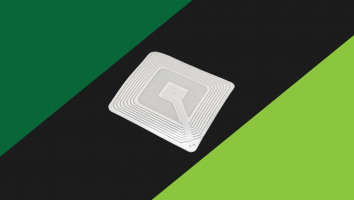

In the ever-evolving landscape of inventory management, technological advancements are driving significant changes for logistics. One such innovation is the adoption of smart labels, including RFID and QR codes. These labels are transforming how businesses track, manage, and optimise their inventory. Today, we’ll explore the benefits of smart labels and how they are revolutionising inventory management.

The Rise of Smart Labels

Smart labels, equipped with technologies like RFID (Radio Frequency Identification) and QR (Quick Response) codes, offer a seamless and efficient way to manage inventory. Unlike traditional barcode labels, smart labels provide real-time data and enhanced tracking capabilities, allowing businesses to streamline their operations.

Benefits of RFID Labels in Inventory Management

- Real-Time Tracking: RFID labels enable real-time tracking of inventory. Unlike barcodes, which require line-of-sight scanning, RFID tags can be read remotely and simultaneously. This allows for instant updates on inventory levels, locations, and movements, ensuring accurate and up-to-date information.

- Increased Accuracy: With RFID labels, the margin for human error is significantly reduced. Automated scanning and data entry eliminate the risk of manual errors, leading to more accurate inventory records. This accuracy is crucial for maintaining optimal stock levels and preventing overstocking or stockouts.

- Efficiency and Speed: RFID technology speeds up the inventory management process. Large quantities of items can be scanned quickly and efficiently, reducing the time required for inventory counts and audits. This increased speed allows businesses to allocate resources more effectively and improve overall operational efficiency.

- Enhanced Security: RFID labels enhance security by providing detailed information about each item’s movement. This visibility helps prevent theft, loss, and misplacement of inventory. Businesses can track products throughout the supply chain, ensuring they reach their intended destinations securely.

Advantages of QR Codes in Inventory Management

- Accessibility: QR codes are easily accessible and can be scanned using smartphones or tablets. This accessibility makes it convenient for employees to update inventory records on the go, facilitating real-time data entry and management.

- Versatility: QR codes can store a wide range of information, including product details, batch numbers, and expiration dates. This versatility allows businesses to provide comprehensive information about their inventory, improving traceability and transparency.

- Cost-Effective: Implementing QR codes is a cost-effective solution for businesses of all sizes. The technology is relatively inexpensive and can be easily integrated into existing inventory management systems. This affordability makes it an attractive option for businesses looking to enhance their inventory tracking capabilities without significant investment.

Revolutionising Inventory Management

The integration of smart labels into inventory management systems is revolutionising the way businesses operate. By leveraging RFID and QR code technologies, companies can achieve greater accuracy, efficiency, and control over their inventory. These advancements lead to better decision-making, reduced operational costs, and improved customer satisfaction.

Smart labels also provide valuable insights into inventory patterns and trends. Businesses can analyse data collected from RFID and QR code scans to identify slow-moving items, optimise stock levels, and streamline their supply chains. This data-driven approach enables proactive inventory management and helps businesses stay ahead of market demands.

The benefits of RFID and QR codes, including real-time tracking, increased accuracy, efficiency, enhanced security, and cost-effectiveness, are driving significant improvements in how businesses manage their inventory. As technology continues to evolve, the adoption of smart labels will become increasingly essential for businesses aiming to optimise their operations and stay competitive.

Stay tuned to Alliance Label’s News Page to keep up with all the latest blogs and updates!